Limecrete

The breathable, more flexible alternative to concrete

What is limecrete?

Limecrete is a combination of natural hydraulic lime and lightweight aggregate or sand, which can be used as an alternative to concrete. This creates a breathable floor slab with a certain amount of flex.

We never include any cement in our limecrete as this would reduce its breathability. We do, however, add fibres to strengthen the floor further.

What is a limecrete floor?

We offer two types of limecrete floor – the slab and screed floor and the slabless floor. Over the last decade, more architects and customers have opted for the slabless floor design. It is the most cost-effective option, and the floor build-up requires a shallower depth. In both floor types the insulative and non capillary base of Recycled Foam Glass (RFG) is laid and compressed prior to limecrete.

Slab and Screed

A slab and screed design consists of a compacted layer of recycled foam glass on top of a prepared sub-base and geotextile membrane. This is followed by another layer of geotextile and a limecrete slab made with insulative pumice aggregate. If underfloor heating is required, this is installed on top of the slab, followed by a limecrete screed.

We usually see the slab and screed design with larger, more extensive project where further work is planned after subfloor installation, such as to walls or ceilings, but before underfloor heating. Slab and screed is often specified in churches and cathedrals where it is a longer project with a lot of high level work needing to be done before the underfloor heating or final floor finish is installed.

Download our cross section and schedule suggestion for the Slab and screed option

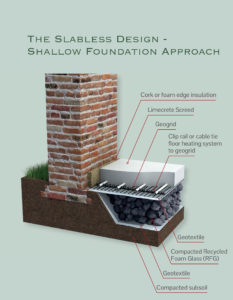

Slabless

A slabless limecrete floor consists of a compacted layer of RFG insulation on too of a prepared subbase and geotextile membrane. This is followed by another layer of geotextile and limecrete screed, produced using washed sharp sand and fibre re-enforcement.

This is the most common type of limecrete floor design that we see. The main benefits of this design are the lower costs, reduced depths and a shorter time frame required to complete the work.

Download our cross section and schedule suggestion for the Slab-less option

We successfully work with limecrete inside during the winter by heating the water. The ambient temperature of the room then needs to be maintained at 5 deg Celsius or higher.

The floor can be designed to suit individual requirements and achieve required U-Values. We are able to assist with this process.

We have addressed some frequently asked questions in our Limecrete FAQ. Please contact The Limecrete Company if you need any more information.

We are featured in an issue of Listed Heritage Magazine. As seen in Listed Heritage, membership journal of the Listed Property Owner’s Club.

Read an article we wrote for Ecclesiastical and Heritage World (July 2011) Limecrete Solutions.

We are prominently featured on the blog Designed to Breath following the construction of a low impact, straw bale house in Cambridgeshire. The blog contains interesting photos, videos and information on limecrete and other sustainable building technologies.

You may also be interested in hempcrete.